It is production costs optimization for reproducible elements up to 50% in comparison with machining.

Production

If you decide to cooperate with our company, Odlewy Cisnieniowe, Odlewnia Ritter (Pressure Foundries, Ritter Foundry), you will receive a finished product, manufactured in a professional foundry, where the knowledge and theory gained at the AGH University of Science and Technology in Krakow is supported by many years of experience.

The company Odlewy Cisnieniowe,

Odlewnia Ritter

(Pressure Foundries, Ritter Foundry)

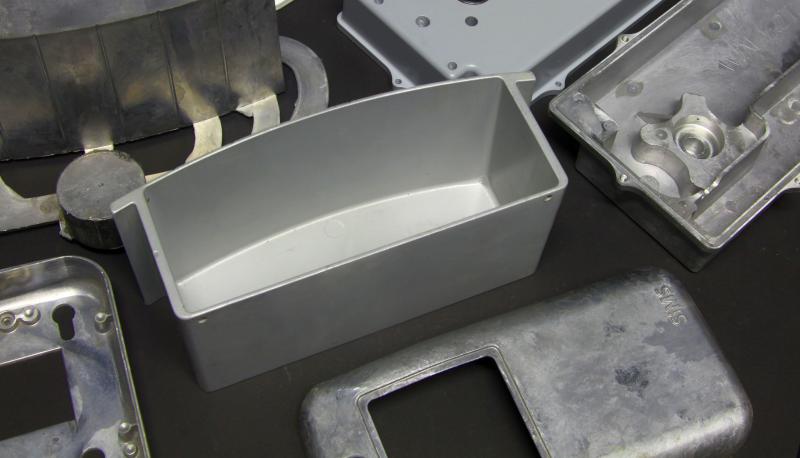

It deals with the preparation of a complete detail production, which can be made of aluminum, zinc alloy or brass.

Production of foundry molds

Our company is able to optimize and technologicalise a detail, which is a difficult thing.

This activity requires knowledge and experience of a constructor, a foundry technologist. In addition, our company has its own tool room, where we are able to produce a high-pressure die casting mold at a competitive price, single-cavity or multi-cavity, depending on the complexity of the detail.

It is possible to make a slide mold, which does not require further processing of the detail. We encourage you to submit inquiries.

Our casting machines:

We have pressure cast machines with clamping force of 200 and 300 tons. They are equipped with bipolar hydraulic-oil pumps and pressure batteries to reinforce the shot. Thanks to them, they are able to press the material at a speed of 700 km/h and under high pressure (30-250 MPa).

Colosio

- work table dimensions: 680mm x 690mm

- distance between posts: 430mm

- possibility of making casts up to 1kg

Vacuum furnaces

We are equipped with vacuum casting technology. With its help, we can cast acid resistant steel or even titanium.

Toshiba

- work table dimensions: 880mm x 880mm

- distance between posts: 520mm

- possibility of making casts up to 3kg

These machines enable us to carry out small series and mass production at a competitive price.

We have our own mold casings, which enables us to adapt the mold insert itself. Thanks to this treatment, the cost of the mold is significantly reduced.

Basing on our knowledge and experience, we will be happy to advise each client on the method of production and selection of material which should be used to produce a detail.