We offer machining on professional machining centers, we accept orders for milling and turning on cnc machines.

Offer

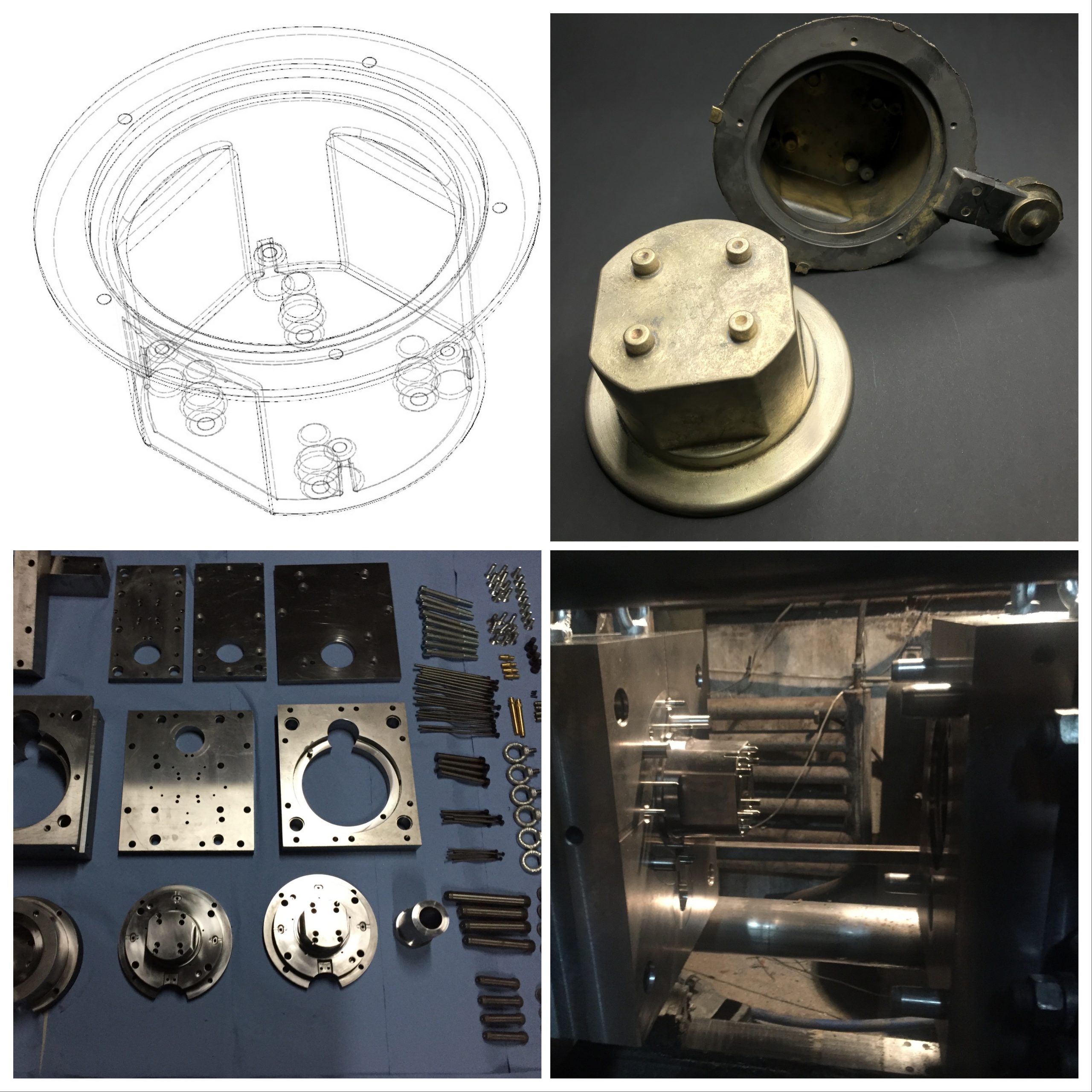

1. Conceptual design detail optimization

when we start working on a new detail, we use CAD and MES technologies. We provide the client with casting solutions so that the detail is demouldable and retains its usefulness

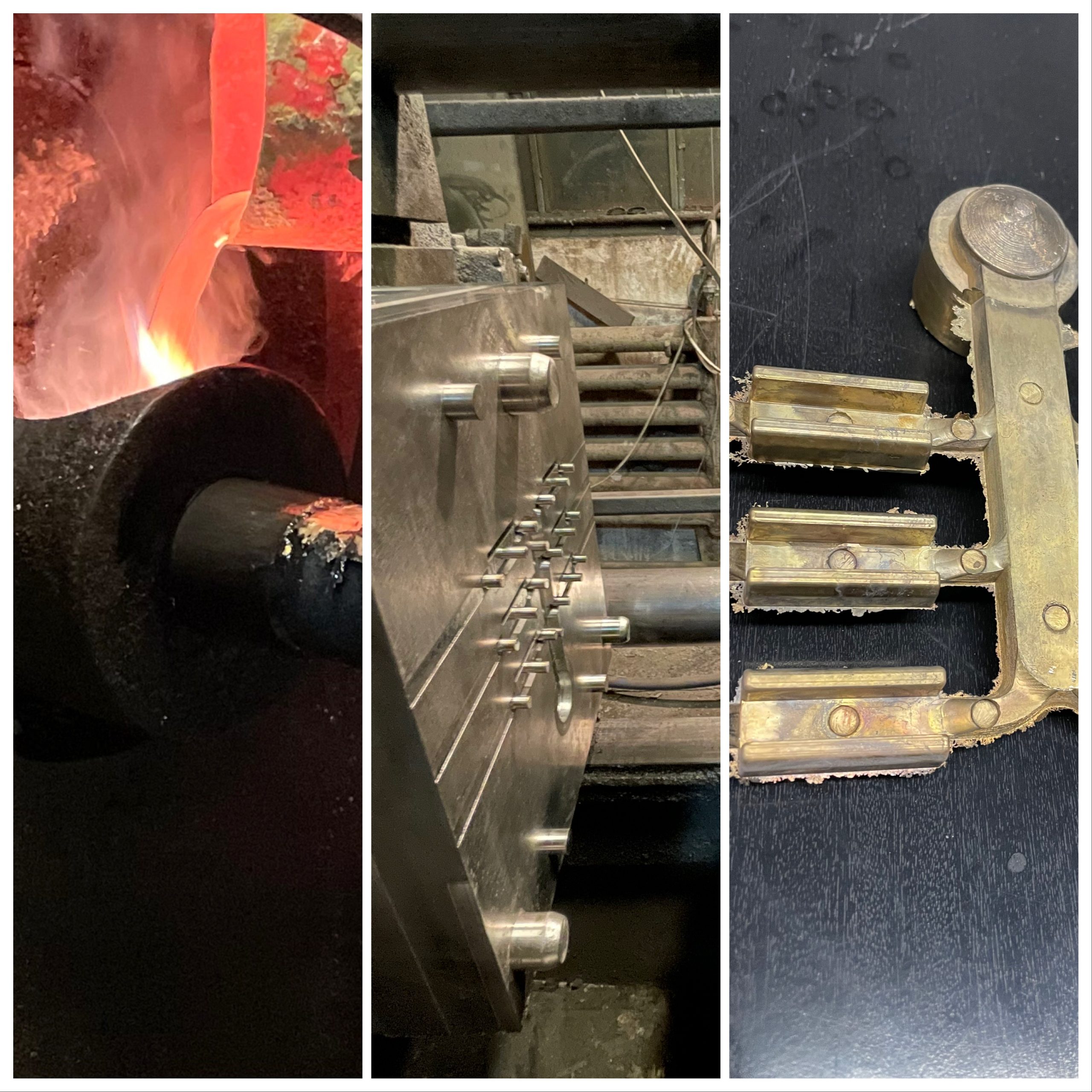

2. Making the mold

after the customer's approval, we proceed to make the mold in WCL steel with hardness level of approximately 53HRC. Processing such a hard material requires a lot of experience.

3. Small and large-scale production of details from non-ferrous metals and ZnAl

the production process is carried out in accordance with the schedule presented by the client and the deadlines for completion in our company are given priority

4. Machining

the process of finishing the detail in our company is fully automated, we build tools for machining castings that ensure repeatability and high quality of cutting

5. Machining of details tumble finishing or rotofinish

according to our process, the edges of the detail are rounded with the use of rotovibration processing, which facilitates further finishing of the detail

6. Application of galvanic coatings such as copper, nickel, chrome

to meet the customer's requirements, we have the option of electroplating coatings on cast details, not only brass but also aluminum

7. Anodizing of details - technical anode

this process ensures high anti-corrosion resistance even in sea conditions, our details pass tests in salt chambers, simulating the time of 3 years at sea

8. Powder coating - sintering according to the RAL palette

typical finish of cast details is refined by us through many years of trials with various paint suppliers, contrary to appearances, painting the cast is not so obvious

We guarantee competitive prices and timely execution of orders while maintaining the highest quality of services.

We have CNC machines from Haas company, which are used for machining casts as well as production of molds or details.

- frezarka Haas:406x305x254

- frezarka Haas:660x356x500

- frezarka Haas:1270x508x635

- frezarka bramowa:800×600

- tokarka Siemens:320×500

Our company has over 30 tons of conventional machines and accessories for the production of tools, which allows us to keep mold prices at a reasonable level.